Custom TPN Compound Machine: Safe and Efficient Compounding

Making Total Parenteral Nutrition (TPN) is an important and complicated task in modern pharmacies. Pharmacy technicians and healthcare providers face challenges like contamination and calculation mistakes. They also deal with slow work processes.

In this article, we will explore the advanced features and benefits. Also, explore best practices for using custom TPN compound machines. We will also discuss industry-leading solutions. These include the Baxter TPN Compounder and EXACTAMIX TPN systems.

What is a Custom TPN Compound Machine?

A Custom TPN Compound Machine is a modern device. It makes it easier to prepare safe and sterile nutritional mixtures. These machines help prevent mistakes and reduce contamination risks. This machine makes work easier for healthcare providers.

Custom machines use barcode scanning, weight checks, and automated software to improve safety. They also help meet regulatory standards like USP 797.

Key Features of the Custom TPN Compound Machine

1. Advanced Automation

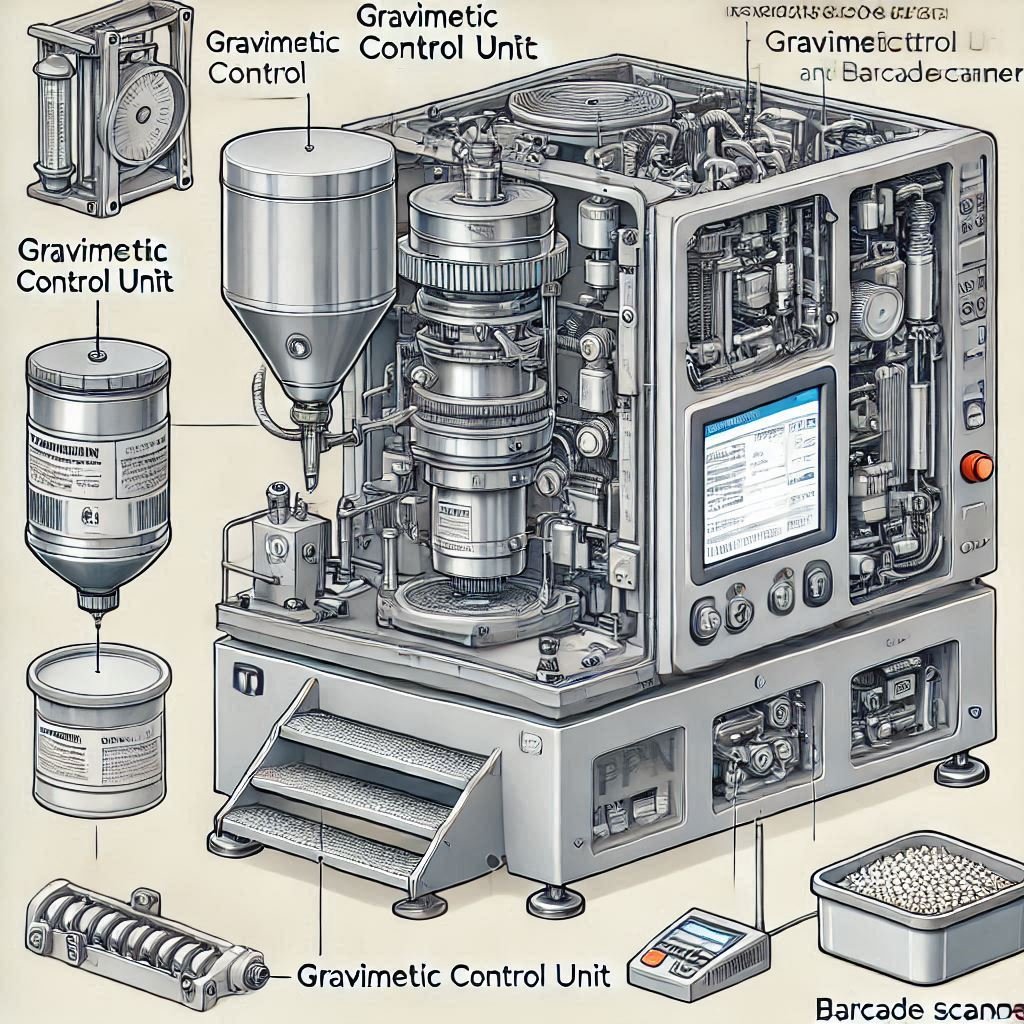

- Gravimetric Control Unit: Ensures precise measurement with built-in load-cell calibration using certified weights.

- Micro-Volume Dispensing: Allows for the preparation of highly accurate dosages. It contains dispensing as low as 0.2 mL.

2. Safety Enhancements

- Air Bubble and Occlusion Detection: Integrated sensors ensure safe and uninterrupted fluid flow.

- Barcode Scanning and Verification: Tracks source containers and ensures proper ingredient selection.

3. User-Friendly Software

- NutriSoft Integration: Automates order entry, prevents drug incompatibility, and streamlines workflows.

- Remote Access Capability: Enables troubleshooting and technical support 24/7.

4. Compatibility and Scalability

- Supports various container types, including bags, vials, and syringes.

- Bidirectional communication with HIS/EHR systems using HL7, JSON, or XML.

Difficulties in TPN Preparation

Contamination Risks

Every needle insertion into vials or IV bags poses a contamination risk. Traditional methods often lack proper aseptic controls, leading to compromised product sterility. Custom TPN compound machines lower risks by using sealed enclosures. And also by controlled airflow and touchless controls. These features help ensure safety and prevent contamination.

Manual Errors

Manual TPN preparation requires complex calculations, which can result in mistakes in dosage and ingredient mixing. Automated software integrated into machines. These machines like the Baxter TPN Compounder and EXACTAMIX TPN ensure accurate formulations.

Workflow Inefficiencies

Pharmacies face delays due to repetitive manual tasks. Custom machines reduce these inefficiencies by automating the preparation and verification processes.

Comparing Industry-Leading TPN Compounders

| Feature | Baxter TPN Compounder | EXACTAMIX TPN | Custom TPN Compound Machine |

| Price | Competitive | Premium | Moderate |

| Precision | High | Very High | Extremely High |

| Software Integration | Limited | Advanced | Advanced |

| User-Friendliness | Moderate | High | Very High |

| Contamination Prevention | Standard | Enhanced | Superior |

Best Practices for Operating a TPN Compounding Machine

1. Optimal Placement

Place the machine inside a properly designed cleanroom or positive pressure isolator. It is used to maintain unidirectional airflow and sterility.

2. Regular Calibration

Use certified calibration weights, such as the KS-240-KA. It is used to ensure consistent accuracy of the gravimetric control unit.

3. Aseptic Techniques

Technicians should change gloves frequently and avoid contact with non-sterile surfaces. It ensures all components are within the laminar airflow zone.

4. Routine Maintenance

Schedule regular cleaning, decontamination, and smoke pattern tests. It is used to identify airflow disruptions and particulate accumulation.

Benefits of Upgrading to Advanced TPN Compounders

Enhanced Patient Safety

Automated checks for ingredient compatibility, calcium/phosphate solubility, and osmolarity limits. It ensures safe patient formulations.

Time and Cost Efficiency

Custom machines reduce preparation time by up to 50%. It allows pharmacy staff to focus on critical patient care tasks. Integration with systems like NutriSoft also tracks inventory and reduces waste.

Compliance with Standards

Compliance with USP 797, ASHP, and other regulatory guidelines. It ensures sterility and safety in every preparation.

Innovations in TPN Compounding: XLTC Series Enclosures

The XLTC series by Aseptic Enclosures offers custom isolators. It eliminates contamination risks and improves operator safety. By housing the compound in a positive-pressure environment. The XLTC ensures the sterility of every compounded product.

Conclusion

The Custom TPN Compound Machine is changing how pharmacies make sterile TPN solutions. By integrating advanced safety features, user-friendly software, and scalable automation. These machines address the critical pain points of contamination, inefficiency, and manual errors.

Whether you choose the Baxter TPN Compounder, EXACTAMIX TPN, or a custom solution. It’s important to invest in the right equipment. It ensures better patient outcomes and compliance with industry standards. Upgrade your TPN compounding process today for a safer and more efficient future.

FAQs

What is ExactaMix?

ExactaMix is a system used for the automated preparation of Total Parenteral Nutrition (TPN) solutions, ensuring accuracy and efficiency in the process.

What is a TPN machine?

A TPN machine is designed to prepare sterile Total Parenteral Nutrition solutions, helping pharmacies safely mix nutrients for patients who cannot eat or drink.

What is the largest medical device recall?

The largest medical device recall was related to Philips CPAP, BiPAP, and ventilator devices in 2021, due to issues with sound-dampening foam that posed health risks.

What is the recall on Baxter Healthcare?

Baxter Healthcare had a recall in 2021 for certain lots of its infusion pumps due to a software issue that could potentially lead to incorrect dosing.